RPA is an essential tool for optimizing complex business processes, driving product innovation in the manufacturing industry, and helping companies automate mundane tasks such as inventory management, invoice processing, supply chain automation, customer service, purchase order (PO) management, etc., by lowering costs across the board with increased efficiency. At Sparsh, we offer a full spectrum of robotic process automation services to manufacturing companies.

RPA enhances the accuracy and speed of business processes by automating rule-based operations. We provide custom RPA solutions for manufacturing companies that automate time-consuming and repetitive rule-based tasks and integrate with existing legacy systems in real-time.

A good inventory management system can enhance company operations while saving time and money. With the introduction of Robotic Process Automation, inventory management has been considerably more simplified and effective.

Ordering, emailing, and delivery tracking may all be automated using RPA. It offers real-time data reports on inventory levels and enables manufacturing organisations to make smarter decisions using past data. Robotic process automation thereby aids in increasing operational effectiveness and lowering expenses.

RPA in the manufacturing industries will use to automate several operations associated with invoicing processing, such as:

Manufacturers can streamline their invoice processing by automating it, leading to both cost and time savings while continuing to foster strong ties with their suppliers.

By leveraging RPA, you can enhance communication with your customers and provide them with the best possible service.

Employees can be reminded to follow up with customers, maintain contact schedules, and escalate complaints using RPA bots.

Front-line employees often have to deal with multiple systems while serving a single customer, which can be very frustrating.

With RPA implementation, you can access data from multiple sources from a single interface. Customer service is made much easier as a result, resulting in a higher level of satisfaction for your customers.

Creating and managing purchase orders (PO) can be a daunting task for manufacturing companies, especially when multiple categories of products are involved. But with the help of RPA bots, the entire purchase order process can be automated according to a predefined rule-based workflow.

This would include extracting relevant data, getting approvals from respective heads through emails, and enabling the smooth creation of PO. With Intelligent automation RPA, the entire process can be streamlined and made much more straightforward, thus saving a lot of time and leading to significant ROI.

The Bill of Materials (BOM) document outlines all components, materials, and assemblies required to manufacture a product. Structured BOM will include information about each component, such as its name, quantity, unit of measure, part number, and supplier. This information lets manufacturers clearly understand the resources needed to produce the desired product. Bill of materials (BOM) is useful in purchasing by helping manufacturers determine which items to order and when to place the orders. Using RPA in the Bill can ensure faster product launches and reduce the risk of costly manual errors. Using Robotic Process Automation in the BOM creation process, manufacturing companies can gather relevant information from multiple sources, including catalogues and internal databases, helping to streamline the development process to maximize business efficiency and accuracy.

RPA services can be used in manufacturing organizations to automate the manual business processes currently slowing down your supply chain. RPA bots extract data from multiple legacy systems and consolidate it into a single database. It will give detailed information on supply chain operations, help you identify areas that need improvement, and lead to significant productivity.

RPA can automate order processing, invoice management, and shipment tracking tasks. RPA automation solutions allows you to focus on essential business tasks, such as developing new relationships with suppliers or exploring new markets.

RPA will use to improve communication across your supply chain and avoids delays. RPA bots can automatically generate reports on shipment status and send them to the appropriate parties.

Deploying RPA bots in your supply chain require proper planning and execution. But the benefits are huge: faster, more efficient supply chain back-office operations can help you stay ahead of the competition.

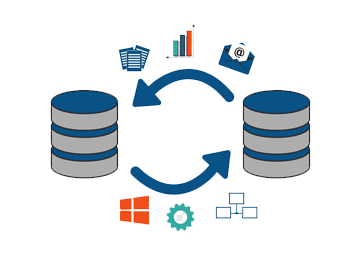

Data migration is physically moving data from one platform to another. Using RPA bots, manufacturing companies reduce the cost of data migration and help manufacturing businesses get the most out of their investments.

ERP automation can help manufacturing enterprises to streamline their operations and improve efficiency. By implementing RPA, companies can free up time by automating tasks and processes typically done manually.

ERP automation can be beneficial in resource planning. Companies can improve accuracy by automating the generation of reports. For example, manufacturing organizations can automatically generate pricing, inventory, Accounts Payable and Receivable reports, and other types of reports. This can help businesses to monitor their operations better and make more informed decisions.

Another area where ERP automation can be beneficial is in the area of manufacturing. RPA automates the inventory management process. Businesses can save time and ensure they always have the necessary materials and supplies. Additionally, using RPA technology companies can automate the reordering process to ensure they never run out of stock.

RPA is associated with manufacturing and can help optimize mundane routine business operations. Using RPA bots, manufacturing companies can free their employees from routine tasks and help them to focus on more value-added tasks.

Introducing RPA in manufacturing companies is experiencing several benefits, like increased control of overall business process improvement, optimized employee performance, significantly lower manufacturing errors, improved quality and excellent ROI.

RPA bots can also help to reduce manufacturing costs by lowering human errors. This is a massive benefit during manufacturing, where a tiny mistake can lead to enormous consequences.

Robotic Process Automation is a technology used in manufacturing companies to streamline routine, time-consuming business operations and augment productivity. RPA in manufacturing industries offers automation solutions for manual tasks, invoice handling, customer service, Bill of Materials, and buying order regulation.

In a manufacturing business, RPA bots will bring great ROI by automating repetitive, time- consuming, mundane tasks, improving business performance, and freeing employees to focus on important activities.

Below are the key steps manufacturing companies will take:

Our custom RPA services associated with the manufacturing industry are tailored for every individual enterprise as per their business needs. From strategy creation to implementation, deployment, and maintenance, our automation solutions help our client companies in achieving the desired results. Take a look at the RPA solutions offered by Sparsh for manufacturing automation are:

Identify Pain

points and

Suitability for

Automation

Advanced Process

Automation

for

unstructured data

Basic Process

Automation using

Rules Engine,

workflow

AI-infused RPA using

Natural Language

Processing, Big Data

etc

Our client is the largest retail seller with multiple stores in the world with global operations across 8 countries.

Listed below are some of the challenges and pain points that our client encountered while processing POS Accounting Process:

The company was looking to automate and transform complete process.

In a shared path, all sales reports will be placed, and bot need to read, and extract required data and save in Excel and accounting software based on rules.

The following is the complete process flow:

Our client is the largest electronic products producer in the world with global operations across 162 countries.

Listed below are some of the challenges and pain points that our client encountered while processing Restriction of Hazardous Substances Process:

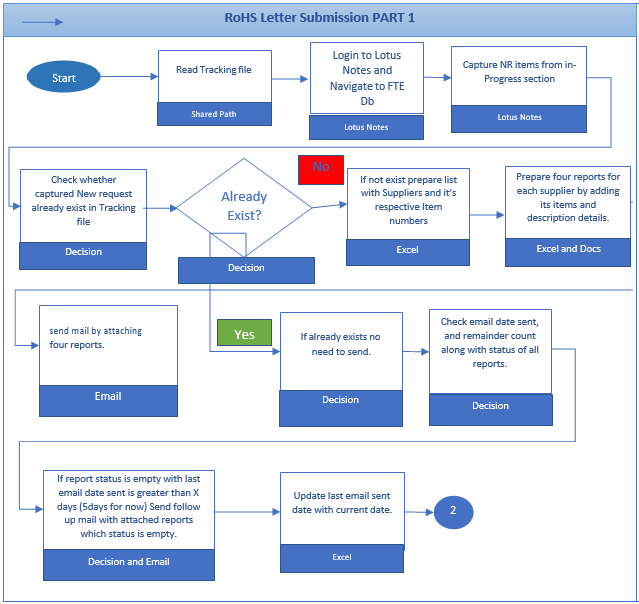

The company was looking to automate and transform a complicated RoHS and Letter Submission process.

Part 1 is to read the new request from lotus notes and prepare four documents with supplier and Item number details and Send email/follow-up mail based on status. Below are reports which we send to supplier:

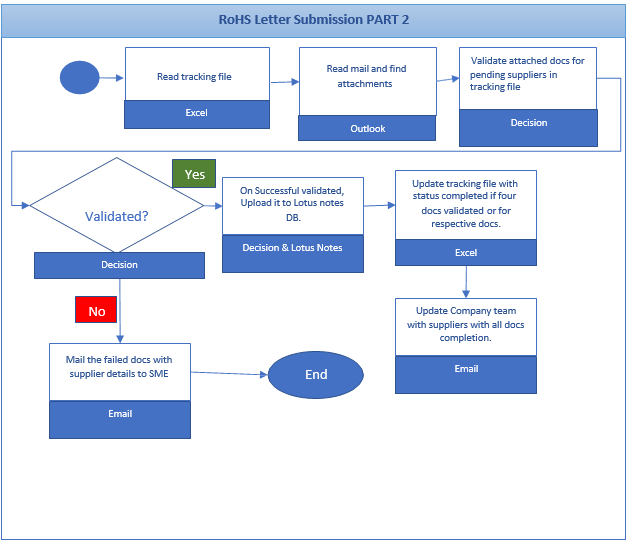

In Part 2 Bot will read the mail and find attachments and validate the documents and upload it to Lotus notes on successful validations. On failed case it will report to staff.

The industry average for RPA is mentioned below and any process which is unable to achieve the following during the discovery stage is usually descoped,